Case Studies

Cold Weather Ammonia Reduction in Municipal/Industrial Treatment Plant

Problem

During cold weather this municipal wastewater treatment plant with a high percentage of industrial flow from food processing and electronics manufacturing suffered from high ammonia loadings. As temperatures dropped the plant lost nitrification. The objective of this full-scale product application program was to reestablish ammonia oxidation and reduce ammonia-nitrogen in the lagoon system during cold weather to below the 3 mg/L permit limits.

Product Used

MICROCAT®-XNC Nitrifier Concentrate

Treatment Process Configuration

Wastewater Flow: 3 MGD (11,363 m3/day) – The wastewater treatment system consists of bar screens and grit chambers, two 15 million gallon (56,818 m3) aerated lagoons in series and two quiescent cells for secondary settling.

Product Application Program

Bioscience, Inc. determined that MICROCAT-XNC was to be added to the second aerated lagoon to avoid the possible toxic effects of the high BOD loading from industrial discharges in the first lagoon. MICROCAT-XNC was added continuously to the second aerated lagoon via a chemical pump system. Alkalinity and pH of thesystem were controlled to optimal conditions for nitrification using soda ash. Lagoon temperature ranged from 10-14 degrees Celsius during the inoculation program.

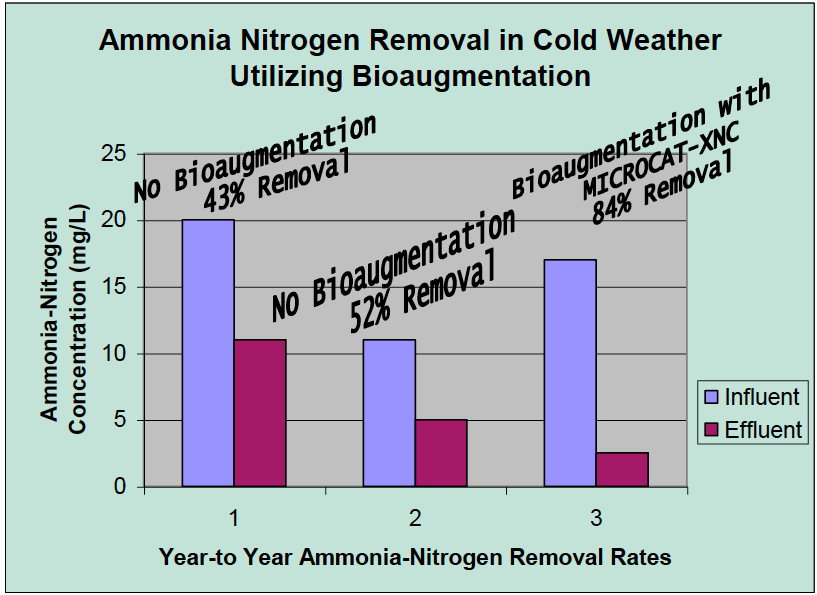

Results (see following chart)

Ammonia-nitrogen removal was 84% during the MICROCAT-XNC addition with an average influent ammonia concentration of 17.4 mg/L, and an average effluent ammonia concentration of 2.8 mg/L. As depicted in the graph, this was significantly better than the two previous years ammonia removal rates of 52% and 43% respectively (both above the permit limit of 3 mg/L). Bioaugmentation with MICROCAT-XNC accomplished the objectives of the program to increase ammonia removal rates and achieve ammonia concentrations below the permit limit.