Anaerobic sludge digesters are very commonly found in both municipal and industrial wastewater treatment settings around the world.

The digester is typically a completely enclosed tank that excludes oxygen from the digester liquids.

The objective of such digesters is to:

- Reduce the mass of solids,

- Stabilize the resulting suspension, and

- Produce a usable gas (methane).

The importance of these objectives varies from country to country and site to site depending on the local economics of sludge disposal and the value of the gas that is produced. Currently, fats oils, and greases (FOG) and/or septage may also be added to the sludge digester to increase gas production and revenue (by charging for the disposal of these residues).

The Biology

A wide range of process configurations are found in the field, but the core anaerobic process generally always involves a two-stage process mediated by two distinct groups of microbes that must operate in concert in order for the process to produce desired results enumerated above. In addition, the growth rate and optimal growth conditions of these two groups of microbes is quite different. In particular, one of these groups ( the methanogens that do the final conversion of organic acids to methane gas) is relatively slow growing and is quite sensitive to a range of commonly-encountered operating conditions.

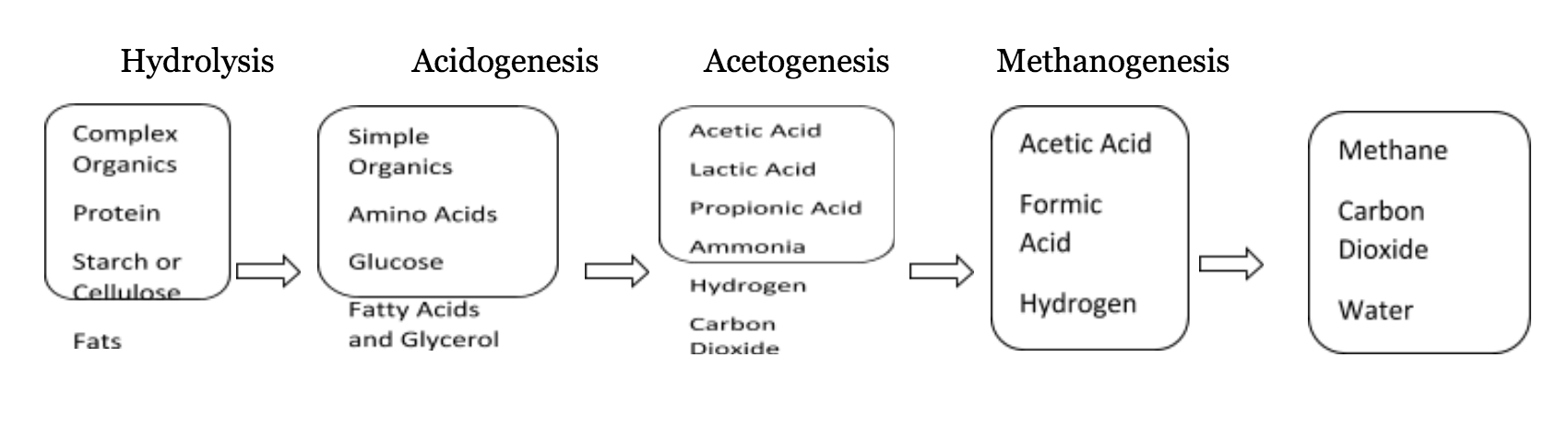

The process follows the sequence:

Stage 1: Hydrolysis converts complex polymeric organic compounds to simple compounds which can be absorbed and metabolized. Acidogenesis breaks these compounds down to volatile fatty acids, carbon dioxide and other low molecular weight compounds. Acetogenesis further converts a variety of simple metabolic products to acetic and formic acids and hydrogen.

Stage 2: Methanogenesis converts hydrogen, formate, acetate and other simple substrates to methane and carbon dioxide.

In stage 1, microbial respiration occurs using any residual dissolved oxygen, nitrate, ferric iron and sulfate as electron acceptors. Various hydrolysis reactions occur, depolymerizing proteins, starch, cellulose and other carbohydrates. Fats are hydrolyzed to glycerol and fatty acids. Fermentation reactions then dominate as these electron acceptors are consumed. The products formed include ammonia, hydrogen sulfide, ferrous iron, hydrogen, propionic, acetic and formic acids. In the absence of further degradation, the pH decreases. These reactions are carried out by facultative and obligate anaerobic bacteria. In some digester designs the stage 1 process is carried out in a separate reactor.

Specialty blends of micronutrients, microbial cultures, microbial growth enhancers and neutralizing agents when added to systems experiencing such problems can be effective in stimulating (and re-establishing, if necessary) properly balanced biological activity in anaerobic sludge digesters.

In stage 2, methane producing archea convert the simple substrates from step 1 to methane using carbon dioxide as the electron acceptor. Bacteria which produce hydrogen may be closely associated with the archea and these organisms are sometimes described as syntrophic or cross-feeding, enabling both to grow in an otherwise non-ideal environment. These archea are slow growing, generally require neutral pH, and extract small amounts of energy from the methane production. Thus, they are easily inhibited by low pH (if the acidogenesis reactions occur too fast for the methanogens to convert the acids to methane and carbon dioxide), dissolved oxygen which is toxic to obligate anaerobes, and various organics or heavy metals. Due to the unique enzymes involved in methogenesis, certain trace metals such as iron, nickel and cobalt may be limiting. Most heavy metals form insoluble compounds with the hydrogen sulfide and are not readily available for incorporation into biomass.

Bioaugmentation

Specialty blends of micronutrients, microbial cultures, microbial growth enhancers and neutralizing agents when added to systems experiencing such problems can be effective in stimulating (and re-establishing, if necessary) properly balanced biological activity in anaerobic sludge digesters. Such blends reestablish the proper nutrient balance, introduce cultures capable of performing the desired tasks, stimulate the growth of the indigenous microbes and assist in buffering the pH of the system to minimize the tendency of the pH to drop. Bioaugmentation of poorly operating sludge digesters can show significant benefits, particularly where gas production has a high value.

Such products are usually mixed with warm water and applied at the rate of 0.5 to 5 pounds per 1000 gallons of digester or system volume. The amount and frequency of addition depend on the frequency and severity of the problem at hand. Appropriate application rates for specific problems may be determined by laboratory treatability testing.